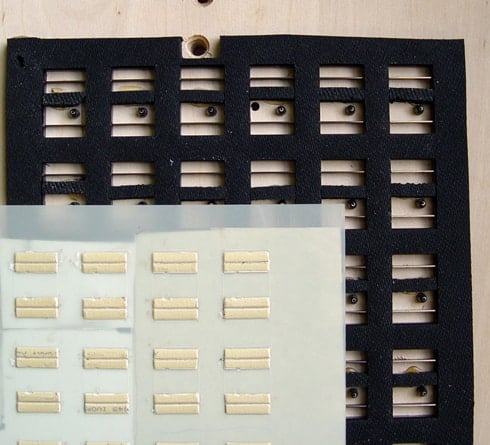

Creasing dies are a great way to create material that can handle a large amount of stress and flexibility. This is achieved through the process of creating an inward bulge between stress points parallel to each other. These steel rule die perforations and creases are made with a special rule that is usually positioned on the same die as the cutting rule within a flat-bed die cutting area. By using a cutting rule, our die cutting & increasing services are able to create a creased perforation without cutting all the way through the material.

Creases sometimes require a secondary die called a die cutting matrix. Depending on the amount of crease or bend you want to achieve in the final product you will want to consider how hard the material will be hit in the press, the type of material you are creasing, whether a matrix is used or not and what type of creasing rule is used.